The process of making a ring

Are you curious to know how a ring is made from A to Z? For us, it's our daily bread but we understand that an element of mystery hangs over the design of a custom piece of jewelry . The process of creating a ring is a series of precise actions carried out by meticulous craftsmen. Without going into details, expanding on all the techniques and covering all the ring models, we will give a brief overview of the different manufacturing stages and in what order they follow each other.

The sketch

It all starts with an idea… like a marriage proposal. The creation of a piece of jewelry , whether it is an engagement ring, a diamond ring or a simple silver ring, begins with a drawing. Initially a simple sketch, it is defined by its details, its shapes by adding the colors of metals and precious stones. It is not uncommon for our designer to create more than ten sketches before the custom piece of jewelry can move on to the second stage.

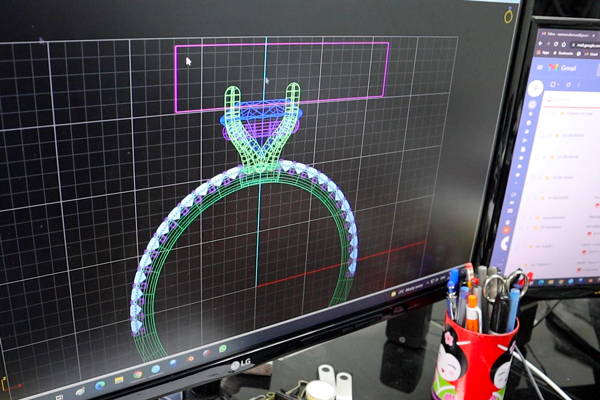

3D drawing and sculpture of a ring

Ring design has changed significantly in recent years with the arrival of 3D computer modeling. Flamme en rose is at the cutting edge of this new technology. From a sketch, the modeler generates a 3-dimensional image of the jewel. This step is very useful since it allows you to clearly visualize and approve the ring model . The model is then printed and forms a wax prototype. However, the carving of some jewelry is done directly in the precious metal and requires a more organic approach. We then cut with a saw called a bocfil and to complete the shape, hollow out and obtain smooth edges, we use files with various grits. The sculpture of a piece of jewelry can also be done in wax. All of these techniques apply to handcrafted jewelry since it requires the meticulous work of an artisan jewelry maker. Years in the business have proven to us that there are at least 5 good reasons to choose handcrafted jewelry.

Casting a ring

Initially, a cast is created in a cylinder containing the wax jewelry. The plaster is then heated and the wax drained, leaving only the wax imprint. A centrifuge is responsible for filling the impression with metal in a liquid state such as gold in the case of a gold ring. This process is called casting. Once cooled, the plaster breaks to reveal the jewelry in one or more pieces. It goes without saying that this step is not necessary if the jewelry is carved directly from the metal.

Preparing to set a ring

When the jewelry comes out of the casting, the metal is dull. A first polishing is necessary to reach certain parts that are more difficult to access. This is also the step where we add texture to the precious metal if the design requires it. Texturing is done using different techniques, the most common of which are hammering, punching and chiseling. Next comes the welding of the parts with a precise torch, an alloy with a lower melting point and a flux to protect the surface to be welded. When creating an engagement ring , we assemble the head of a ring to its body. To clean the oxidation caused by the torch flame on the ring, a liquid solution called deroché is used. The jeweler then checks the solidity and cleanliness of the solder and ensures that the jewel is straight.

Setting a ring

Setting is the action of fixing natural or laboratory-created precious stones into the metal setting of the jewelry. The crimper uses a binocular magnifying glass that magnifies our natural vision up to 20 times. This tool can precisely set stones as small as one millimeter. He drills cavities with a rotating tool and fixes the stone with a bead adjusted to the size of the setting. When the head of a ring contains prongs, it closes them on the stones so that they can no longer move.

Finishing a ring

Once the ring creation is formed, textured and assembled with the set stones, the last step is to clean the jewelry from top to bottom so that it shines in all its glory. First there is the grinding carried out with a mandrel fitted with very fine sandpaper which removes any visible scratches. Then there is the polishing which is carried out with a machine with a rotary motor. In order to obtain a mirror polished finish, the jewel is coated with a polishing paste commonly called red and it is rubbed on the brushes which rotate at high speed. Some brushes give the jewelry a brushed appearance. After polishing, some paste coatings remain embedded in the cavities. They can be easily removed when the jewelry is soaked in an ultrasonic bath.

Creating an engagement ring

The jeweller's online Flamme en rose offers a wide choice of ring models for all budgets and tastes. All these models initially come from the creation of custom rings that we molded in order to be able to reproduce them. Creating custom rings will remain a true passion for us. Since 2009, we have created more than 500 unique pieces. Watch the video below to see in detail the steps of creating a ring with precious stones and come meet us to create a tailor-made engagement ring to your taste.

Get an online consultation with one of our jewelers today.